Labs & equipment

Our facilities enable researchers and industry leaders to develop cost-effective, net-zero energy buildings that produce as much energy as they use.

FBLFuture Buildings Laboratory

Concordia University’s Future Buildings Laboratory will support research to advance knowledge, best practices, and innovation in sustainable buildings and infrastructure now and for the future.

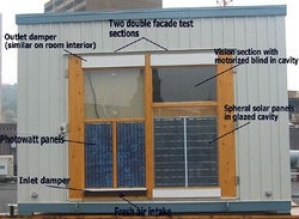

Buildings of the future need to be intelligent, self-sustained, and meet the needs of occupants at the minimum cost to the environment while being resilient and adaptive to climate change. Located on the Loyola Campus, the Future Buildings Lab (FBL) is a unique testing facility offering world-class multidisciplinary research and an educational platform supporting research in advancing knowledge, best practices, and innovation in sustainable buildings and infrastructure. This $1.27M CFI facility supports cutting-edge research in three innovative areas: 1) Energy positive building envelopes and integration with HVAC systems; 2) Intelligent building operation, and 3) optimization of residential nano-grid with renewable sources and electric vehicles.

The Solar Simulator - Environmental Chamber laboratory is an internationally unique facility developed with a $4.6 M grant from the Knowledge and Infrastructure Program (KIP). It enables accurate and repeatable testing of solar systems and advanced building envelopes under standard test conditions with full simulated sun and indoor plus outdoor conditions. It consists of two major systems:

- A large scale solar simulator is designed to reproduce natural sunlight in order to test various solar systems such as photovoltaic modules, photovoltaic/thermal modules such as the JMSB solar system, solar air collectors, solar water collectors and a range of building-integrated solar systems.

- Specific capabilities of solar simulator (testing at room conditions)

- Consists of 8 special metal halide (MHG) lamps with an artificial sky to remove infrared radiation from lamps (lamps individually controlled and dimmable); meets the specifications of the relevant standards EN 12975:2006 and ISO 9806-1:1994.

- Collimation: approximately 80% of the emitted radiation lies in the range in which the incidence angle modifier of a regular flat plate collector varies by no more than 2%

- Test specimen size: up to 2.4 m x 3.2 m

- Less than ± 10% homogeneity, under 1-sun (depending on test specimen size)

- Customized solar air collector testing platform (able to test systems such as the JMSB BIPV/T system)

A two-storey high environmental chamber with a mobile solar simulator lamp field used to test building technologies under controlled environmental condition (from arctic to desert).

Specific capabilities of environmental chamber

- Test wall systems and rooms up to 3 m wide x 7 m high, for hygrothermal and energy performance, including solar electricity and useful heat generation

- Temperature test range: -40° to 50°C , under specific conditions

- Temperature stability can be maintained within 1°C

- Relative humidity range between 20% – 95% (depends on temperature)

- Specially designed windows that allow through sunlight produced by a 6-lamp mobile solar simulator

A variety of equipment has been acquired, including solar and lighting instruments, particle image velocimetry system, heat flow meters. Our lab also includes an artificial sky (3 x 3 x 3 m) facility. The main tests being performed in this lab consist of testing of motorized shading devices in conjunction with dimmable lighting. Industry partners include Philips and Unicel Architectural.

A variety of equipment has been acquired, including solar and lighting instruments, particle image velocimetry system, heat flow meters. Our lab also includes an artificial sky (3 x 3 x 3 m) facility. The main tests being performed in this lab consist of testing of motorized shading devices in conjunction with dimmable lighting. Industry partners include Philips and Unicel Architectural.

A typical test hut as the one shown in the Figure would have dimensions of 8' x 8' x 10' high (2.5 m x 2.5 m x 3.0 m). The exteriors of the test panels are installed in an inverted sense so that exterior surfaces face inward. Hence, the interior of the inverted test hut is exposed to the outdoor environment. A one-ton chiller with reheating heaters provides a simulated "outdoor" temperature condition between -10 to -30°C inside the test hut. While an advanced humidity and temperature conditioning unit (MAPX-6CWL from ESPEC) is being acquired to provide a more precision control of temperatures from -45 to 50°C and RH from 20 to 90%. The constant lab temperature serves as the "indoor" condition for the panels. Currently, the test hut is built with a SIP (structural insulated panel) building system, 142 units of which were designed and are being installed (in 2010-2011) in 14 communities of the Nunavut Territory.

The lab holds the equipment, data acquisition systems (DASs), and instruments from the building envelope lab which was decommissioned in 2009. Two specially designed HVAC systems provide conditioned air from 10 to 35°C, maintain constant relative humidity (RH) levels by using high precision recirculation chillers, and measure the exact amount of water vapor in the return air from test rooms by accurately measuring the condensed water. Several DAS units with a total of more than 1,200 input and output channels allow any complex experimental setup or concurrent tests. An indoorair movement study setup with 18 hot-sphere anemometers and 3 data logging stations can measure spatial distributions and temporal fluctuations in air velocities and temperatures in the test rooms. Many sensors are available for measurement, 10 precision (±1%) and 40 regular (±2 - 3%) RH transmitters, 15 moisture content (MC) transmitters and a customized MC measurement system that use electronic switching module to measure MC at up to 384 locations, 2laminar flow element (LFE, ±0.8 %) for precise flow measurement, 3digital pressure meters with different ranges and two mechanical scanning devices tomeasure differential pressures at up to 48 locations, and, a precision (±0.01 mg) analytical balance. Calibration setups and hand-held meters for the above parameters are also available. There are many other supporting systems and devices, for example 3 industrial process controllers to maintain test conditions and a reference emitter with a temperature bath for infrared thermography (IRT) investigations.

Boundary-layer wind tunnel

The effect of wind on building models is reproduced in a boundary layer wind tunnel. This allows for the measurement of mean and fluctuating wind loads on buildings, air flow around tall buildings and around groups of tall buildings, environmental pedestrian level wind studies, and effluent dispersion (contamination of buildings by smoke and building exhaust from stacks). Computational evaluation of wind effects on buildings is also carried out.

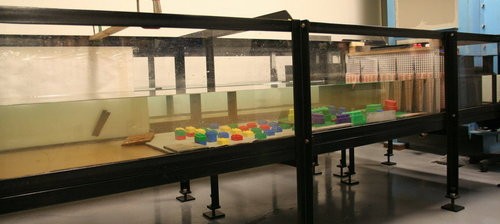

Water flume

A closed-circuit channel (3.0m long and 0.75m wide) is used to visualize the flow around buildings and to investigate snow drifting / accumulation problems associated with buildings.

The Energy Efficiency Laboratory houses an Environmental Chamber with a controlled thermal environment used for different studies related to energy efficiency in buildings, reduced scale air infiltration through walls and rotating doors, thermal comfort and displacement ventilation.

The main goals of research activities carried out in this laboratory are listed below:

- Design and analysis of energy-efficient buildings.

- Sustainable development concept applied to buildings

- Second law analysis of HVAC systems

- Optimization of life cycle performance of buildings and HVAC systems

- Computer modelling of energy performance of buildings and HVAC systems

- Computer modelling of refrigeration systems for ice rinks

- Net zero energy houses

- Analysis and validation of building energy analysis programs.

- Impact of building design and control strategies on thermal comfort

In addition, the laboratory houses equipment for field measurements in existing houses and commercial buildings, which later is used for the development of new assessment methods and measurements techniques, for:

-Evaluation of airtightness of buildings through a depressurisation test using blower door equipment and infrared thermography;

-Monitoring of energy consumption of buildings or HVAC systems;

- Thermal comfort (using thermal comfort meter) and indoor air thermal parameters (air temperature, relative humidity, CO2);

The laboratory has also the capabilities of computer simulation of energy performance of buildings using the state-of-the art packages such as TRNSYS, eQuest, BLAST, HOT-2000, HOT-3000, EES