Gina Cody School researchers innovate to boost safety and productivity on construction sites

New wearable sensors tracks workers' locations, body orientations, and productivity states.

New wearable sensors tracks workers' locations, body orientations, and productivity states.

Ensuring safety and productivity on a construction site is a challenge due to the dynamics of activities and constant movements. In a study published in Automation in Construction, researchers at Concordia’s Gina Cody School of Engineering and Computer Science have developed a real-time monitoring system to address this challenge.

Conducted by Mohammadali Khazen, MSc, along with Professors Mazdak Nik-Bakht and Osama Moselhi from the Department of Building, Civil, and Environmental Engineering, the research introduces a system that tracks workers' locations, body orientations, and productivity states using wearable sensors on their wrist, chest, and hard hat. This system leverages Bluetooth signal strength and body acceleration data to provide valuable insights into workers' activities.

The study was conducted in partnership with ReelyActive and AtkinsRéalis, with funding provided by the Natural Sciences and Engineering Research Council of Canada (NSERC).

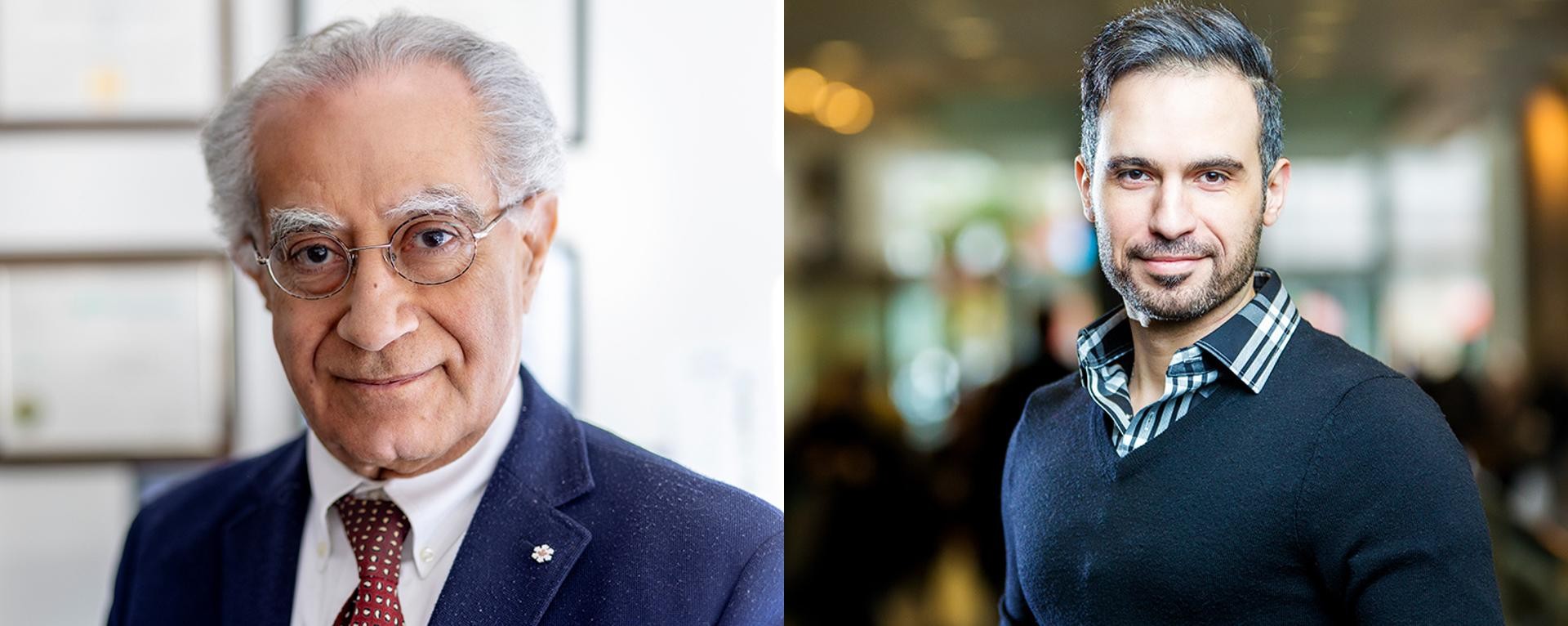

Osama Moselhi and Mazdak Nik-Bakht

Osama Moselhi and Mazdak Nik-Bakht

Tested in a laboratory environment simulating a construction site, this system proved to have several potential applications. It can enhance safety by alerting workers to potential hazards based on their location and orientation. Additionally, it improves productivity by providing detailed data on work states, helping project managers optimize workflows and identify inefficiencies. The modular and easily extendable design makes it suitable for various construction sites with minimal wiring dependency.

Furthermore, the data collected from this system can be used for long-term analysis, helping construction companies develop better safety protocols and productivity benchmarks. By continuously monitoring and analyzing worker activities, companies can identify patterns that lead to inefficiencies or safety risks and take proactive measures to address them.

Find out more about the Centre for Innovation in Construction and Infrastructure Engineering and Management

Find out more about the Department of Building, Civil, and Environmental Engineering